- Home

- Manufacturing Power

- Material

- Highly Purity Synthetic Fused Silica

- High-Purity Fused Quartz Glass, ZCQ-K Series

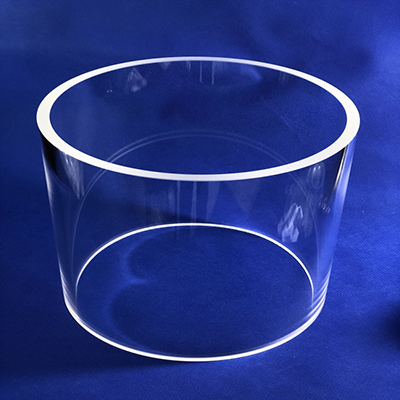

High-Purity Fused Quartz Glass, ZCQ-K Series

High purity, excellent mechanical stability, high temperature resistance, outstanding chemical stability, few bubbles, and customizable size make it optimal materials for various reflectors and sight windows.

| Type | Bubbles and Inclusions | Optical uniformity | Hydroxyl content | Residual strain | Applications | |

| The bubble grade is given for every 100 cm3 | ||||||

| DIN ISO 10110 | Striae | PV value | ppm (μg/g) | nm/cm | ||

| ZCQ-K32 | 1/6x0.3 | No striae in functional direction | < 1x10-5 | ~200 | < 10 | Heat resistant sight window |

| ZCQ-K33 | 1/6x0.1 | No striae in functional direction | < 8x10-6 | ~200 | < 10 | Laser reflective optical applications, heat resistant sight window |

| Type | Bubbles and inclusions | Optical uniformity | Hydroxyl content | Residual strain | Applications | |

| The bubble grade is given for every 100 cm3 | ||||||

| DIN ISO 10110 | Striae | PV value | nm/cm | nm/cm | ||

| ZCQ-K32 | 1/6x0.3 | No striae in functional direction | < 1x10-5 | ~200 | < 10 | Heat resistant sight window |

| ZCQ-K33 | 1/6x0.1 | No striae in functional direction | < 8x10-6 | ~200 | < 10 | Laser reflective optical applications, heat resistant sight window |

| Mechanical Data | ZCQ-K32~33 |

| Density (g/cm3) | 2.203 |

| Modulus of Elasticity (MPa) | 7.25x104 |

| Poisson's Ratio | 0.17 |

| Compressive Strength (MPa) | 1150 |

| Tensile Strength (MPa) | 50 |

| Bending Strength (MPa) | 67 |

| Mohs Hardness | 5.5~6.5 |

| Micro Hardness | 8000~9000 |

| Abbe constant | ZCQ-K |

| Vd=(nd – 1)(nF – nC) | 67.5±0.6 |

| Dispersion constants (Sellmeier) | |

| B1 | 4,76523070x10-1 |

| B2 | 6,27786368x10-1 |

| B3 | 8,72274404x10-1 |

| C1 | 1,18369052x10-2 |

| C2 | 2,84888095x10-3 |

| C3 | 9,56856012x10-1 |

| Dielectric constant (ε) | 0-106Hz | 3x1010Hz | |

| 3.7 | 3.81 | ||

| Dielectric strength in kV/cm | 20°C | 500°C | |

| 250-400 | 40-50 | ||

| Dielectric loss angle (tg δ) | 1KHz | 1MHz-109Hz | 3x1010Hz |

| < 5x10-4 | < 1x10-4 | < 4x10-4 | |

| Resistivity in Ω·cm | 20°C | 100°C | 400°C |

| 1x1018 | 1x1016 | 1x1010 | |

| Resistivity in Ω·cm | 800°C | 1000°C | 1200°C |

| 6.3x106 | 1x106 | 1.3x105 | |

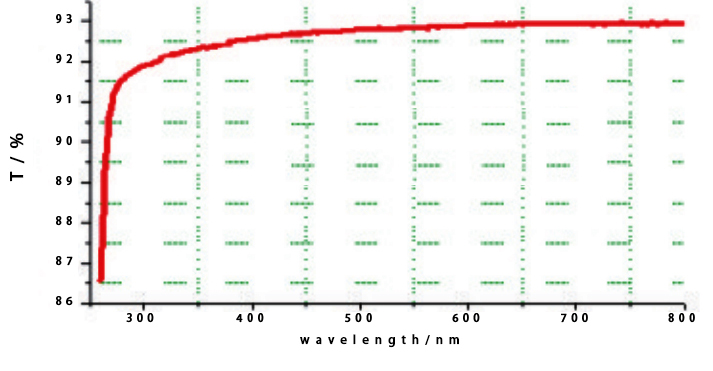

Transmittance Curve (ZCQ-K33 Thickness: 10mm)

| Element | Al | Fe | Ca | Mg | Ti | Ni | Mn | Cu | Li | Na | K | Co | Total |

| ppm | ~20.00 | ~0.20 | ~1.50 | ~0.20 | ~1.30 | ~0.01 | ~0.05 | ~0.02 | ~1.30 | ~2.00 | ~0.40 | ~0.03 | ~28.00 |

| Thermal characteristics | Softening point | Annealing point | Strain point | Max consecutive working temperature | Max working temperature |

| ZCQ-K | 1680°C | 1150°C | 1090°C | 1000°C | 1200°C |

Related Quartz Products

Highly Purity Synthetic Fused Silica is available with 4 series