- Home

- Manufacturing Power

- Material

- Highly Purity Synthetic Fused Silica

- High-purity Synthetic Quartz Glass, ZCQ-H Series

High-purity Synthetic Quartz Glass, ZCQ-H Series

High optical uniformity, no bubbles, weak absorption, as well as customizable size make it the optimal basic materials for viewing windows, lenses, prisms, substrates, and various structural components in various fields of infrared optics and intense lasers.

| Type | Bubbles and Inclusions | Optic uniformity | Hydroxyl content | Residual strain | Applications | |

| The bubble grade is given for every 100 cm3 | ||||||

| DIN ISO 10110 | Striae | PV value | ppm (μg/g) | nm/cm | ||

| ZCQ-H32 | 1/6x0.3 | No striae in functional direction | -- | ~20 | < 10 | IR applications, optical observation window |

| ZCQ-H33 | 1/2x0.01; no bubbles or inclusions>0.01 (mm) | No striae in functional direction | < 5x10-6 | ~5 | < 5 | Full spectrum transmittance applications, pendulous reed with improved stability |

| ZCQ-H34 | 1/2x0.01; no bubbles or inclusions>0.01 (mm) | No striae in functional direction | < 2x10-6 | ~1 | < 5 | High-power laser window, lens, reflecting mirror |

| ZCQ-H35 | 1/2x0.01; no bubbles or inclusions>0.01 (mm) | 3D material no striae in all directions | < 2x10-6 | ~1 | < 5 | Hemispherical gyro, prisms, high precision elements, coated applications |

| Material Grade | Bubbles and Inclusions | Homogeneity | OH-Content | Residual Strain | Application | |

| The bubble grade is given for every 100 cm3 | ||||||

| DIN ISO 10110 | Striae | PV value | ppm (μg/g) | nm/cm | ||

| ZCQ-H32 | 1/6x0.3 | no striae in functional direction | -- | ~20 | < 10 | IR applications, optical observation window |

| ZCQ-H33 | 1/2x0.01; no bubbles or inclusions>0.01 mm | no striae in functional direction | < 5x10-6 | ~5 | < 5 | Full spectrum transmittance applications, pendulous reed with improved stability |

| ZCQ-H34 | 1/2x0.01; no bubbles or inclusions>0.01 mm | no striae in functional direction | < 2x10-6 | ~1 | < 5 | High-power laser window, lens, reflecting mirror |

| ZCQ-H35 | 1/2x0.01; no bubbles or inclusions>0.01 mm | 3D material no striae in all directions | < 2x10-6 | ~1 | < 5 | Hemispherical gyro, prisms, high precision elements, coated applications |

| Mechanical Data | ZCQ-H32 | ZCQ-H34 |

| Density (g/cm3) | 2.203 | 2.201 |

| Modulus of elasticity (MPa) | 7.25x104 | 7.25x104 |

| Poisson's ratio | 0.17 | 0.17 |

| Compressive strength (MPa) | 1150 | 1150 |

| Tensile strength (MPa) | 50 | 50 |

| Bending strength (MPa) | 67 | 67 |

| Mohs hardness | 5.5~6.5 | 5.5~6.5 |

| Micro hardness | 8000~9000 | 8000~9000 |

| Dielectric constant (ε) | 0-106Hz | 3x1010Hz | |

| 3.7 | 3.81 | ||

| Dielectric strength in kV/cm | 20°C | 500°C | |

| 250-400 | 40-50 | ||

| Dielectric loss angle (tg δ) | 1KHz | 1MHz-109Hz | 3x1010Hz |

| < 5x10-4 | < 1x10-4 | < 4x10-4 | |

| Resistivity in Ω·cm | 20°C | 100°C | 400°C |

| 1x1018 | 1x1016 | 1x1010 | |

| Resistivity in Ω·cm | 800°C | 1000°C | 1200°C |

| 6.3x106 | 1x106 | 1.3x105 | |

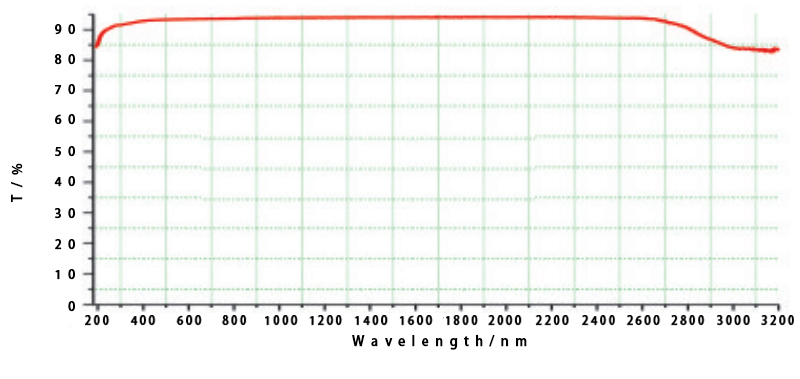

Transmittance Curve (ZCQ-H34 T: 10mm)

| Element | Al | Fe | Ca | Mg | Ti | Ni | Mn | Cu | Li | Na | K | Co | B | Total |

| ppm | ~0.2 | ~0.09 | ~0.08 | ~0.01 | ~0.02 | ~0.01 | ~0.01 | ~0.01 | ~0.01 | ~0.09 | ~0.05 | ~0.01 | ~0.01 | ~0.60 |

Related Quartz Products

Highly Purity Synthetic Fused Silica is available with 4 series